Mashiinka Calaamadaynta Fiber Laser

HORDHAC

Mashiinka calaamadaynta laysarka fiber-ka ayaa ah tignoolajiyada ugu badan ee la aqbali karo ee nidaamyada calaamadaynta laysarka iyada oo ay ugu wacan tahay kala duwanaanshaheeda, dayactirka ugu yar iyo baahida loo qabo alaabooyinka. Si ka duwan Co2, waxay isticmaashaa fiber indhaha ah oo lagu dhejiyay curiyaha dhulka naadir sida isha laysarka waxayna ku calaamadin kartaa xoog badan marka la barbardhigo. Waxay siisaa xalka ugu fiican warshadaha ee aqoonsiga badeecada iyo raadinta.

Maxaad u dooran laser fiber?

Calaamadaynta laserku waa mid joogto ah, dhakhso badan, sax ah oo hadda calaamadaynta iyo xaradhka si fiican loo yaqaan ee birta iyo kuwa aan biraha ahayn. Laysarka calaamadaynta waxay ku shaqeeyaan garaaca laysarka awoodda ugu sarreysa ee gaaban. Awoodda garaaca wadnaha, muddada, iyo soo noqnoqda ayaa go'aamiya tamarta la heli karo, taas oo saameynaysa isdhexgalka ka dhexeeya laydhka laysarka iyo walxaha. Galvo wuxuu ku hagayaa laydhka laysarka xawaaraha sare ee qaybta shaqada. garaac kasta oo laser ah ayaa soo saara pixel.

Waa maxay sababta calaamadaynta laser?

- Habka calaamadaynta joogtada ah & kuwa aan la tirtirin.

- Nooca aan xidhiidhka ahayn - ma soo saaro walaac ama ma beddelo sifooyinka jireed ee alaabta.

Nidaam nadiif ah oo badbaado leh - Kiimikada-ceymiska, biyuhu-ilaalinta, saliidda, dufanka iyo kuwa aan shidaalka lahayn.

- Caalamiga ah Loo Aqbalay Heerka Calaamadaynta Tayada.

- Ma jiro ka-hortag ama ka-hortagista - Waxaa lagu samayn karaa alaabta la dhammeeyey.

-Automated - waxaa lagu dhex dari karaa wax soo saarka ama khadka baakadaha ee jira. Kumbiyuutarka ayaa gacanta ku haya.

- Dabacsan - calaamadee qoraallada, alfanumeric, logos, code-yada bar, sawirada, sawirada, koodka xogta 2D iwm.

- Waxyeellada - ma saamayso tayada calaamadaynta.

-Waqtiga ugu yar ee la dejiyo - looma baahna qalabayn iyo jiingado loo baahan yahay.

- Ma jiraan wax la isticmaalo.

- Waxay kor u qaadaysaa bilicda & qiimaha lacageed ee alaabta.

- Ka-hortagga been-abuurka & been-abuurka, daba-galka badeecada & aqoonsiga iyo wixii la mid ah.

CODSIGA

Mashiinka calaamadaynta Fiber laser wuxuu ku habboon yahay biraha kala duwan (SS, MS, aluminium, dahab, qalin, iwm), daawaha, walxaha oksaydhka macdan ah iyo qaar ka mid ah waxyaabaha aan birta ahayn (Wafer silicon, ceramics, caag, caag, resin epoxy, ABS, qalin daabacaadda, dhejinta, buufinta, iyo filimka dahaarka, iwm

FAAHFAAHIN

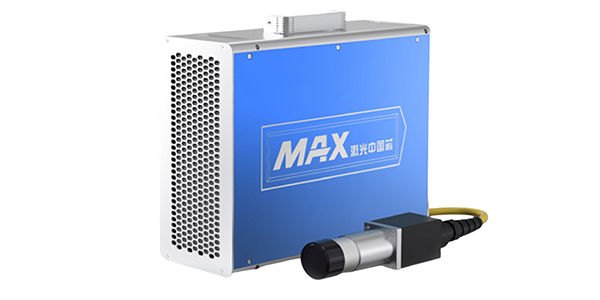

Isha laser MAX, heerka fashilka hooseeya, tayada wanaagsan, wakhtiga nolosha 100000 saacadood, RAYCUS, JPT iyo isha IPG ee ikhtiyaarka ah

Nidaamka xakamaynta JCZ iyo software EZCAD oo leh waxqabad xasilloon iyo kalsooni sare, mashiinka oo ay ku jiraan kombuyuutar, ka hor inta aan la keenin, software iyo parameter ayaa la dhigay.

SINO galvo oo ay ku qalabaysan tahay matoor yar, xawaare dheereeya, saxnaan sare iyo nolol dheer, oo leh tilmaame iftiin cas oo laba jibaaran ayaa ka caawiya macmiilka inuu si dhakhso leh oo fudud u diirada saaro.

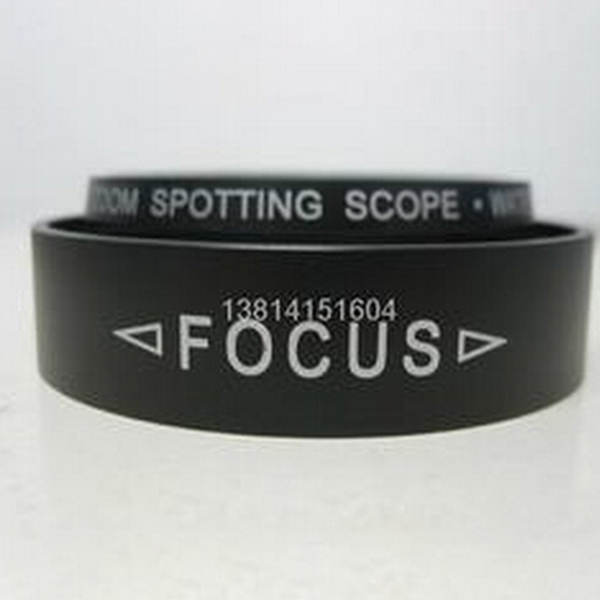

Muraayadaha goobta oo leh aragti iftiin wanaagsan, iftiin isku mid ah, cabbir yar, oo ku habboon jawi adag

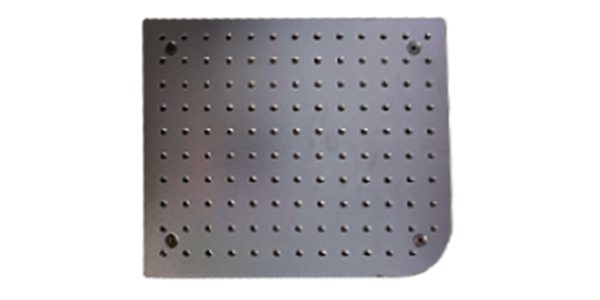

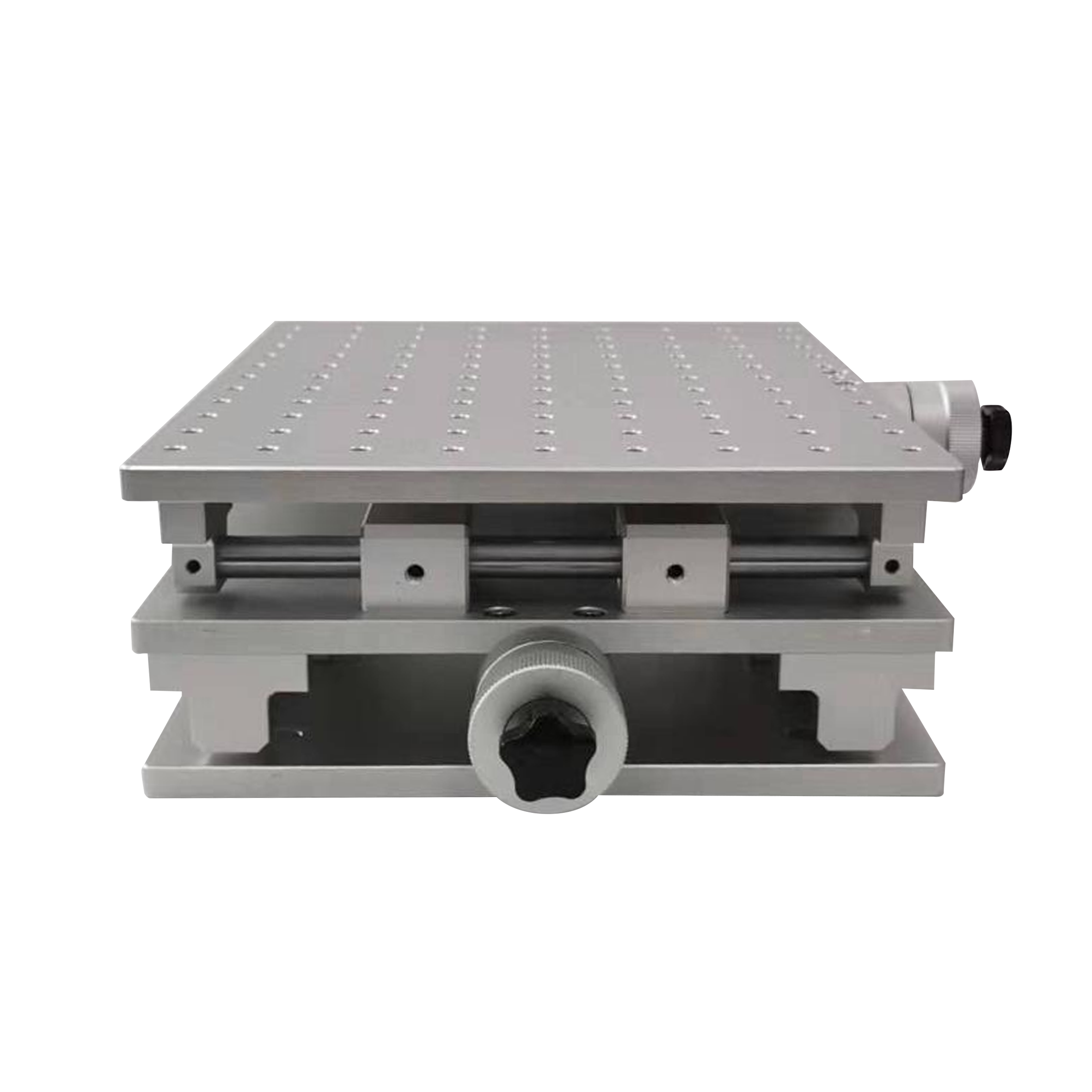

Miiska shaqadu wuxuu leeyahay godadka meelaynta caadiga ah, meelayn ku haboon oo degdeg ah, waa lagu hagaajin karaa si loo daboolo baahiyo kala duwan, hagaajinta hufnaanta shaqada

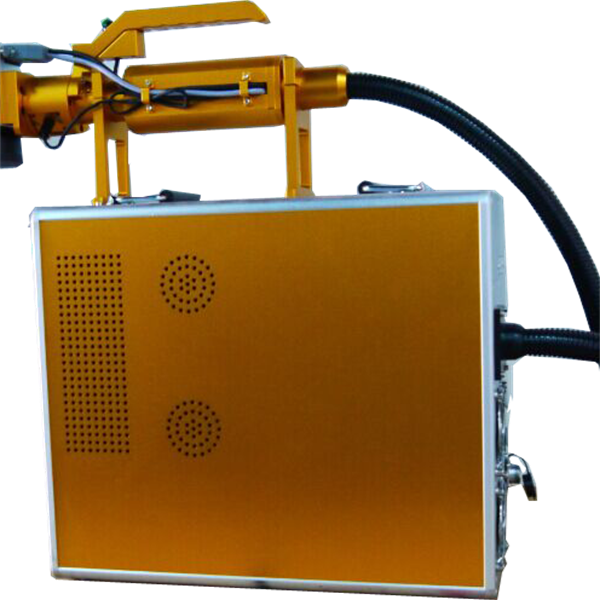

Kor u qaad adigoo isticmaalaya walxo aad u fiican, wax ku ool ah oo deggan, saxnaanta meelaynta sare, adkaanta

PARAAMETER

| Awoodda leysarka:20W/30W/50W/100W | Aagga calaamadaynta: 110 x 110mm / 200 x200mm / 300 x 300mm |

| Xakameeyaha: JCZ | Software: EZCad |

| Qalabka laser: MAX Ikhtiyaarka: Raycus /IPG/JPT | Dhererka mowjadda laser:1064nm |

| M2/Beam tayada M2: <1.2 | Min. Xariiqda Ballaca: 0.01mm (0.0004) |

| Min. Xarafka: 0.2mm (0.008") | Korontada: 220V/50Hz/1kVA |

| Habka qaboojinta: qaboojinta hawada | Xawaaraha xardho:7000mm/s (275IPS) |

MUSUUL

OPTION

Rotary

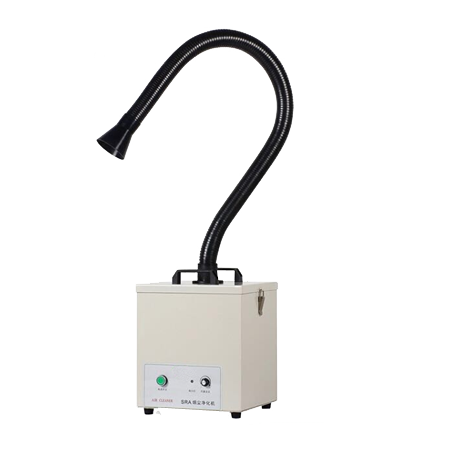

Boodhka ururiyaha

2D/3D miiska

Moodooyinka KALE

Adeeg la habeeyey ayaa la heli karaa iyadoo loo eegayo alaabtaada iyo shuruudaha calaamadaynta.